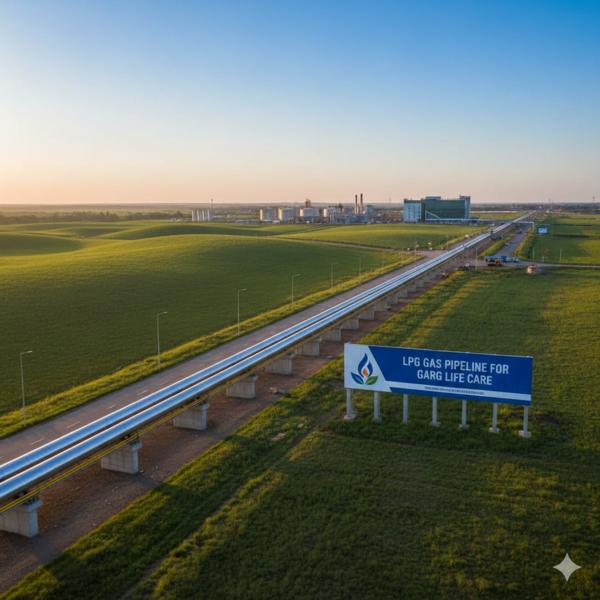

oxygen pipeline by garg life care

Oxygen pipeline installation content

Installing an oxygen pipeline system requires careful planning, adherence to safety standards, and proper execution. Here’s a comprehensive guide to the installation process:

1. Planning and Design

Assessment:

Evaluate Needs: Determine the oxygen demand, flow rate, and pressure requirements.

Site Survey: Assess the layout of the building or facility, noting the locations where oxygen will be used.

Design:

System Design: Design the pipeline system to ensure an efficient flow of oxygen from the source to the end-users.

Material Selection: Choose materials compatible with oxygen, typically copper or stainless steel pipes.

Compliance: Ensure the design complies with relevant standards (e.g., NFPA 99 for healthcare facilities).

2. Preparation

Procurement:

Materials: Acquire pipes, valves, fittings, pressure regulators, flow meters, and other necessary components.

Safety Equipment: Obtain safety gear, including gloves, goggles, and fire extinguishers.

Site Preparation:

Clear Area: Ensure the installation area is free from obstructions.

Labeling: Clearly mark the locations for pipe runs and equipment installations.

3. Installation

Piping:

Pipe Cutting and Preparation: Cut pipes to the required lengths, ensuring clean and square edges.

Cleaning: Thoroughly clean the pipes to remove any oil, grease, or dirt.

Joining: Use appropriate joining methods (e.g., brazing for copper pipes). Ensure joints are leak-free and meet standards.

Supports and Hangers:

Mounting: Securely mount pipes using supports and hangers to prevent sagging and movement.

Spacing: Follow guidelines for spacing of supports to ensure structural integrity.

Valves and Fittings:

Installation: Install valves, pressure regulators, and other fittings as per the design.

Accessibility: Ensure valves and regulators are accessible for maintenance and operation.

4. System Components

Oxygen Source:

Connection: Properly connect the pipeline to the oxygen source, whether it’s a bulk storage tank, cylinder, or oxygen concentrator.

Safety: Install backflow preventers and check valves to prevent contamination.

Control and Monitoring:

Regulators: Install pressure regulators to control the pressure within the pipeline.

Flow Meters: Use flow meters to monitor the oxygen flow rate.

5. Testing and Commissioning

Leak Testing:

Pressure Test: Perform a pressure test to ensure there are no leaks in the system. Use a test pressure higher than the operating pressure.

Soap Solution: Apply a soap solution to joints and fittings to detect any leaks visually.

Purging:

Cleaning: Purge the system with oxygen to remove any residual contaminants.

Flow Check: Verify that the oxygen flows correctly and consistently throughout the system.

6. Safety and Compliance

Safety Checks:

Fire Safety: Ensure all fire safety measures are in place, including fire extinguishers and fire-resistant materials.

Signage: Post appropriate signs indicating the presence of oxygen pipelines.

Documentation:

Records: Maintain detailed records of the installation, including design drawings, material certifications, and test results.

Training: Provide training to staff on the safe operation and maintenance of the oxygen pipeline system.

7. Maintenance

Routine Checks:

Inspection: Regularly inspect the pipeline system for signs of wear, damage, or leaks.

Servicing: Service valves, regulators, and other components as per the manufacturer’s recommendations.

Emergency Procedures:

Response Plan: Develop and implement an emergency response plan for oxygen-related incidents.

By following these steps, you can ensure a safe and effective oxygen pipeline installation that meets the necessary standards and requirements.

Keywords

oil

dirt

NFPA

wear

garg

clean

leaks

place

steps

Needs

staff

layout

gloves

damage

grease

joints

Control

Hangers

Spacing

Purging

goggles

sagging

lengths

Signage

Mounting

Supports

presence

required

facility

Labeling

building

Training

movement

cylinder

end-users

locations

adherence

Servicing

life care

pipe runs

Clear Area

Inspection

Monitoring

Connection

Flow Check

guidelines

safety gear

Site Survey

flow meters

copper pipes

manufacturer

obstructions

Pipe Cutting

square edges

test results

System Design

Documentation

Accessibility

contamination

Soap Solution

oxygen demand

Oxygen Source

test pressure

Pressure Test

other fittings

Service valves

safe operation

efficient flow

design drawings

recommendations

careful planning

other components

detailed records

Site Preparation

oxygen flow rate

Safety Equipment

safety standards

oxygen pipelines

proper execution

bulk storage tank

Design Assessment

installation area

appropriate signs

fire extinguishers

Material Selection

operating pressure

relevant standards

necessary standards

Installation Piping

pressure regulators

oxygen concentrator

backflow preventers

comprehensive guide

4. System Components

structural integrity

installation process

Emergency Procedures

fire safety measures

healthcare facilities

pressure requirements

stainless steel pipes

residual contaminants

oxygen pipeline system

emergency response plan

Preparation Procurement

material certifications

equipment installations

oxygen-related incidents

fire-resistant materials

Compliance Safety Checks

other necessary components

Maintenance Routine Checks

Commissioning Leak Testing

appropriate joining methods

Oxygen pipeline installation content

effective oxygen pipeline installation